The ULTRA

The ULTRA means doing the same job the Classic does, but taking it to the highest possible standard, regardles of labor, time, or resources involved, and setting the cleanest possible path between the components to be connected.

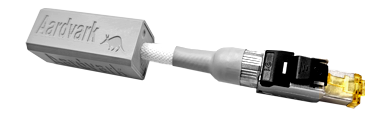

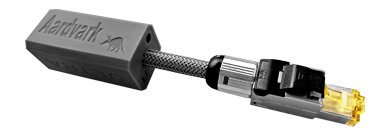

It implements a high quality transformer, in a copper and mu-metal extremely heavy shielded cable and enclosure combo. As the Classic, it is hard-wired, silver alloy hand soldered, every wire, one by one.

The reason

As said before, noise is the basic enemy, and there are three different noise sources to be addressed.

One. The intrinsic noise of the connected devices, as ALL of them have their amount of noise, bigger or smaller, because digital needs clocks to work, and every oscillator is intrinsically noisy.

As noise travels through the ground plane, and all devices have their own amount of noise, it is important then to confine that noise where it is and not allow it to pollute the ground plane.

Hence a high-quality transformer. No electrical continuity.

Two. The signal path itself. Should be as clean, direct, and as high quality connected as possible. In that sense, boards, friction connections, and interconnecting pieces of any kind are avoided. That is the reason for the hard-wired connection and silver alloy soldering.

These two issues are being taking care of already very well by the Classic. As good as the ULTRA.

But there is a third issue that the ULTRA takes special care of, the external EMI.

As mentioned before, electronic components, and high-end music systems are no exception, are plagued by electromagnetic interference. This insidious type of noise floats around all electrical devices.

The Classic is very well shielded, no doubt about that.

But with its extreme, meticulous and time-demanding, heavy copper and mu-metal shielding, the ULTRA takes EMI protection to another level.

It takes it as close to the edge of infeasible as possible. So, outside noise stays absolutely outside.

This way, the ULTRA addresses all three issues in its particular, and most effective, possible way.

The process

Many manufacturers, industrial and semi-industrial, even the best, implement high-grade field assembly RJ45 plugs that are excellent for fast repairing on the field. That means fast termination, but “fast” doesn’t mean “best”. In this case fast means wires hooked to a small board, board that in time is hooked into the plug. In other words, friction connection/contact in every conductor. That is the procedure even with the best of plugs manufacturers, even the most famous ones.

On top of that no extra shielding to EMI but the provided by the plug manufacturer itself.

In the ULTRA, RJ45 plugs are internally coated with heavy EMI shielding, and then hard-wired and silver alloy hand soldered, every wire, one by one.

The same procedure is performed on the transformer end of the cable.

No intermediate connectors, no boards or friction contacts.

It takes many hours to manufacture just one of them.

That is why Aardvark products are artisanal, and will always stay artisanal. There is no way to manufacture them in an industrial level of any kind.